Machinery

Just as every type of paper is tailored to yield a specific desired outcome, we take it upon ourselves to select what fits your customized printing needs from our range of printing machines. The different categories we can offer you are listed as follows:

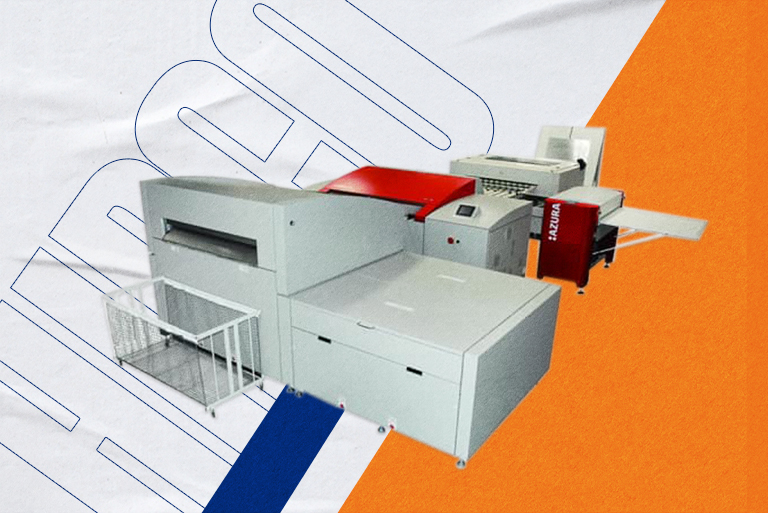

Printing machines

With increasing demand on flexibility, quality, and speed, the machinery at HIPCO requires constant changeover and incorporation to the latest developments and trends.

Offset

Prepress

Postpress

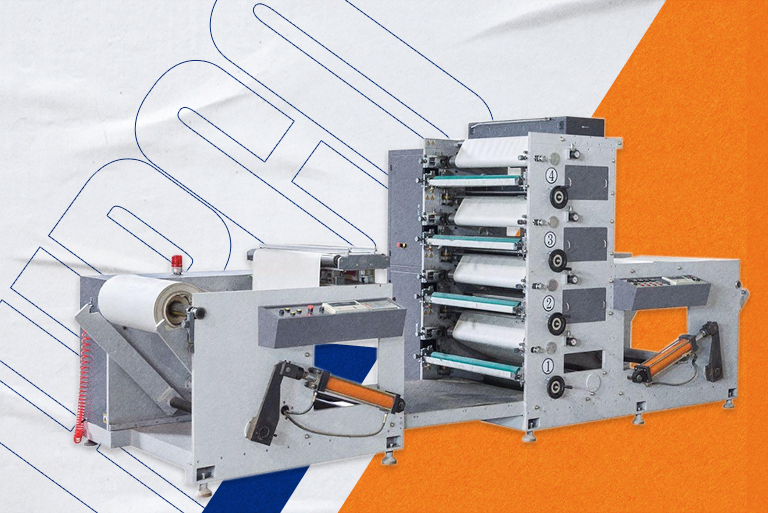

Flexographic

Rotogravure

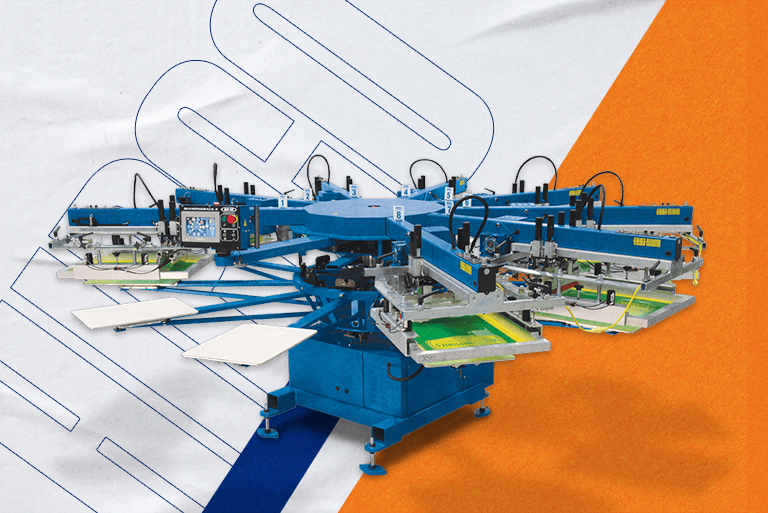

Screen

Wide format

Digital

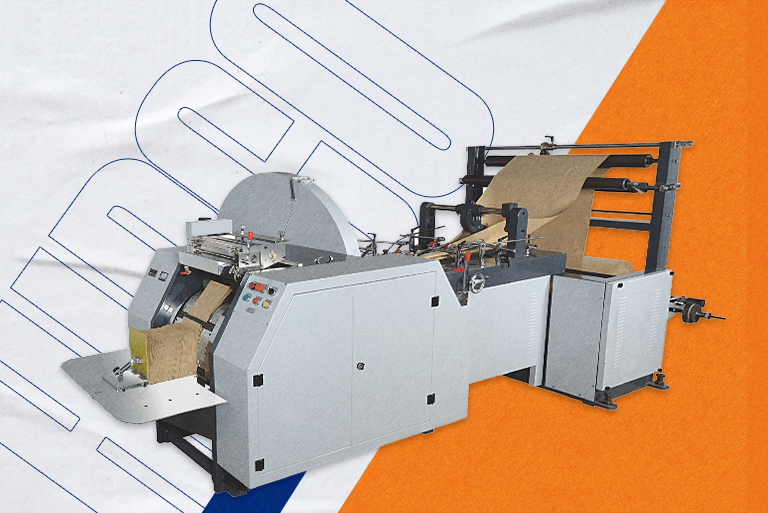

Converting machines

Our specialized machinery helps realize your vision, translating it into paper. These specialty machines take continuous rolls of thin, flat materials, converting them into your desired final product.

Sheeters

Slitters/Rewinders

Forming

Paper Bags

Rotogravure

Security machines

Security printing comprises a number of categories and is utilized to ward off illegal activities such as forgery, counterfeiting, and tampering.

Hologram

Stamp Numbering

Perforating

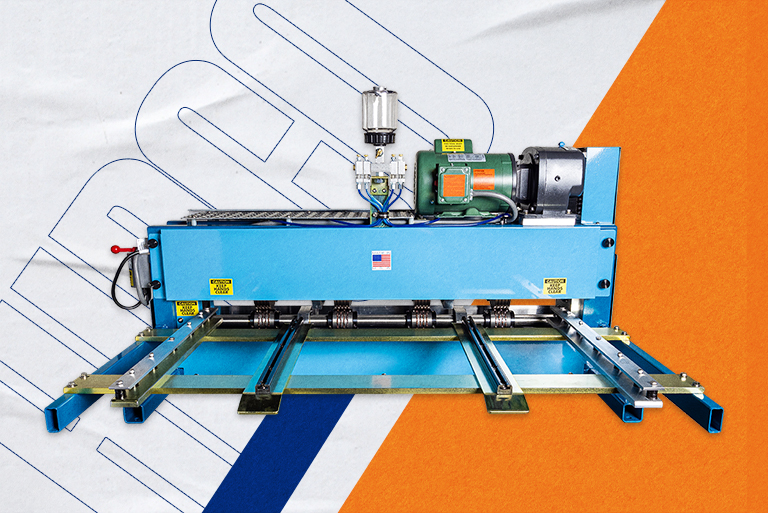

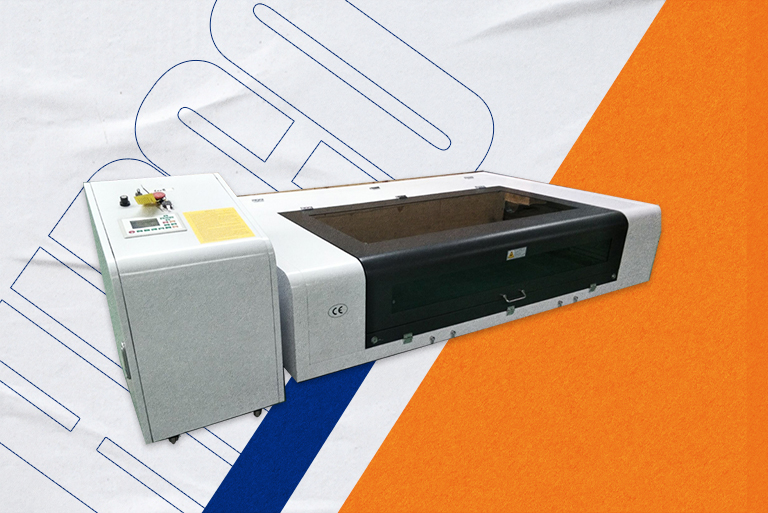

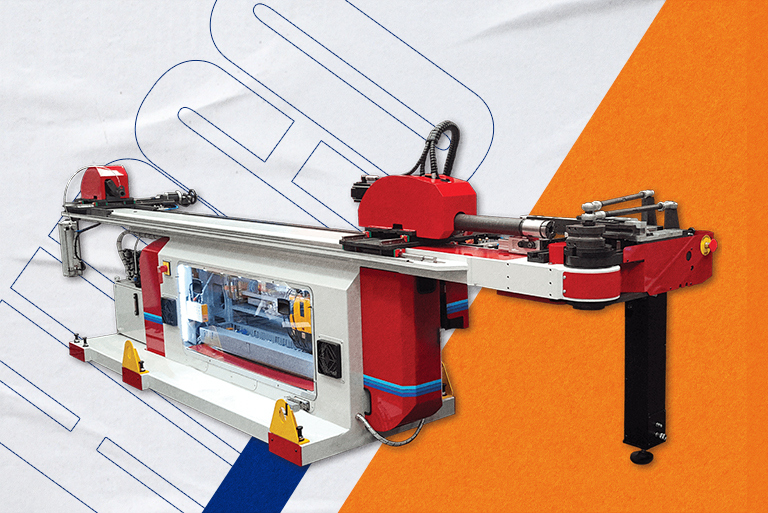

Non-printing machines

Our wide selection of machines and additional services ensure that even your non-printing necessities are fulfilled, guaranteeing you find everything you need for the implementation of your projects.

CNC

Laser Engraving

Bending

Transformers Production Line